Go behind the scenes at The Oak cooperage and learn about the influence of American oak on Silver Oak Cabernets.

Influenced by Oak

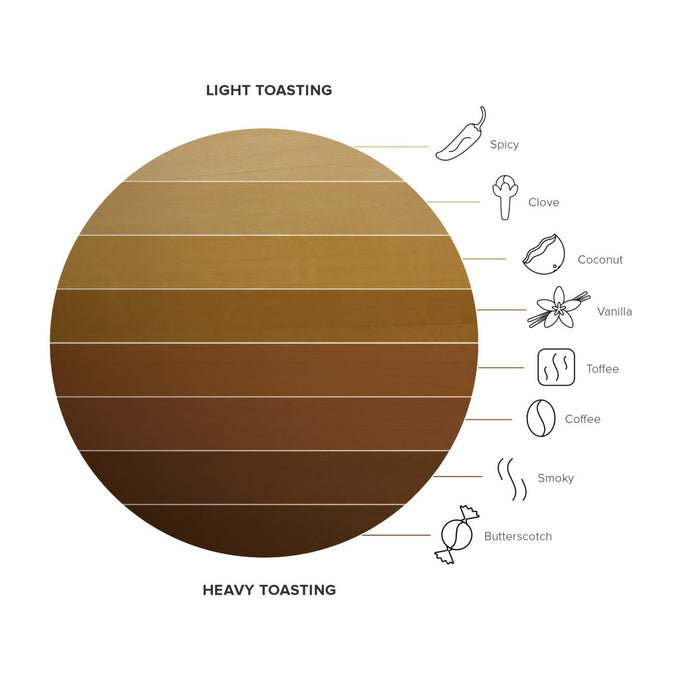

Toasted to Perfection

From Seed to Stave

Sense of Place

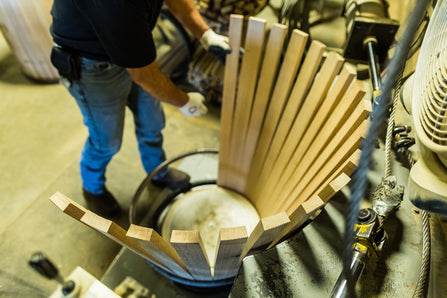

Preparing Wood Staves

Seasoned the Old-Fashioned Way

Step 1: Set Up

The master cooper selects the optimal staves for a Silver Oak barrel. He inspects the grain, sap flow marks, knots, worm holes and even the pattern in the grain. Every barrel has 32 staves carefully arranged in a specific pattern. The set-up is a puzzle as each stave varies slightly in width and a barrel cannot have any gaps.

Step 2: Bending

To bend the staves into the barrel shape without cracking the wood, each barrel is warmed over an open fire. Once the outside of the barrel reaches 300˚F, temporary hoops are placed on the barrel by a hydraulic machine to force the barrel into shape.

Step 3: Toasting

The newly shaped barrel returns to the fire for toasting. It takes approximately 40 minutes to obtain the medium light toasting preferred for Silver Oak barrels. Toasting crystalizes natural sugars in the wood, releasing aromas of freshly baked bread and roasted marshmallows. The freshly toasted barrels go through another round of quality control after which the barrel is capped with round barrel heads.

Step 4: Hooping

The temporary hoops that had been applied to the ends of the barrel during bending are removed and replaced with two new, clean and permanent galvanized steel hoops on each end. Temporary hoops around the belly of the barrel are removed, but before new hoops are secured, the outside of the barrel is sanded down, creating a pristine and smooth finish. After sanding, the final hoops are hammered and nailed on.

Step 5: The Final Touches

Each finished barrel is iron-branded with The Oak Cooperage logo and sanded one last time to remove any final scuff marks before being shipped to Silver Oak.